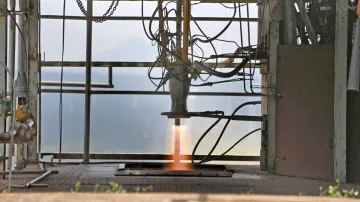

ISRO achieved a significant milestone on May 9, 2024, with the successful hot testing of a liquid rocket engine that was manufactured using Additive Manufacturing (AM) technology. The engine, which was used in the PS4 engine of PSLV upper stage, was tested for a duration of 665 s. The PS4 engine, which has a thrust of 7.33 kN in vacuum conditions, is used in the fourth stage of PSLV and in the Reaction Control System (RCS) of the first stage (PS1) of PSLV.

The engine was redesigned by LPSC to make it amenable to the Design for Additive Manufacturing (DfAM) concept. This approach resulted in significant advantages for the engine. The Laser Powder Bed Fusion technique employed has brought down the number of parts from 14 to a single-piece and eliminated 19 weld joints. This saved significantly on the raw material usage per engine, reducing it from 565 kg of forgings and sheets to only 13.7 kg of metal powder per engine. Additionally, the overall production time was reduced by 60%. The engine was manufactured by M/s WIPRO 3D in the Indian industry and was hot tested at ISRO Propulsion Complex, Mahendragiri.

The engine uses the earth-storable bipropellant combinations of Nitrogen Tetroxide as an oxidizer and Mono Methyl Hydrazine as fuel in pressure-fed mode. It was developed by the Liquid Propulsion Systems Centre (LPSC), ISRO.

As part of the development program, the injector head of the engine was created and successfully tested under high-temperature conditions. Before the hot test, detailed flow and thermal modelling, structural simulation, and cold flow characterization of the proto hardware were conducted to ensure confidence in the engine's performance. As a result, four successful developmental hot tests of the integrated engine were conducted for a total duration of 74 seconds, which validated the engine performance parameters. Furthermore, the engine was successfully tested for the full qualification duration of 665 seconds, and all performance parameters were observed to be as expected. It is planned to include this AM PS4 engine into the regular PSLV program.

ALSO READ: Boeing Starliner capsule carrying Sunita Williams and Butch Wilmore to take off on May 17 now